ADVANCED 2D & 3D TECHNIQUES AND MESHING

IMPLEMENTING A COOLING PIPE

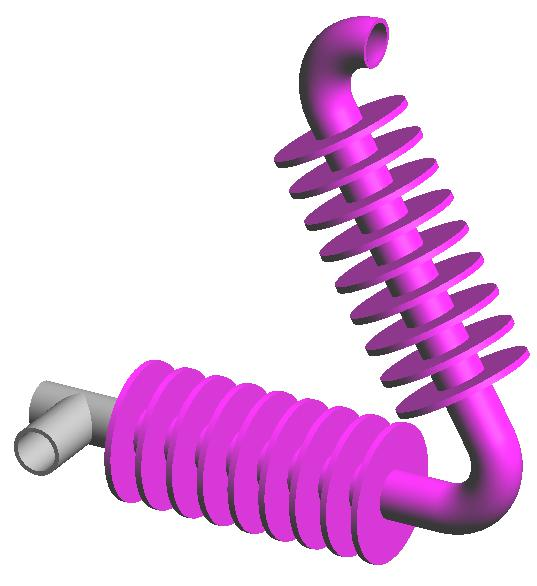

This case study shows the modeling of a more complex piece and concludes with a detailed explanation of the corresponding meshing process. The piece is a cooling pipe composed of two sections forming a 60-degree angle.

The modeling process consists of four steps:

- Modeling the main pipes

- Modeling the elbow between the two main pipes, using a different file

- Importing the elbow to the main file

- Generating the mesh for the resulting piece

At the end of this case study, you should be able to use the CAD tools available in GiD as well as the options for generating meshes and visualizing the result.